Automated Shot Peening Machines

IPS designs and builds advanced CNC and robotic shot peening machines that deliver unmatched precision, repeatability, and compliance with AMS2432 standards. Engineered for aerospace, automotive, and other high-performance industries, our systems combine the accuracy of CNC controls with the flexibility of robotic integration to meet the most demanding specifications. With configurable and custom solutions, IPS machines provide consistent results, improved efficiency, and the durability to perform in even the most challenging production environments. When quality and compliance are critical, IPS shot peening machines set the global standard.

Which peening machine is right for me?

Indexing Turntable Machines

Best for: High-volume, repetitive part processing

Key Advantage: Multiple parts processed simultaneously in a continuous cycle

Strengths: Maximum throughput, reduced downtime, consistent repeatability

Ideal Applications: Aerospace, automotive, and industrial batch production

CNC Rotary Table Machines

Best for: Large or complex parts with intricate geometries

Key Advantage: Programmable multi-axis motion for precision and flexibility

Strengths: Uniform coverage on challenging shapes, high accuracy, adaptable tooling

Ideal Applications: Aerospace, energy, and specialized industrial components

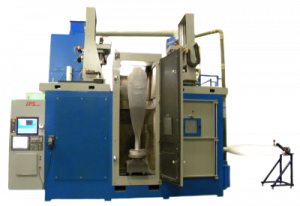

CNC Indexing Turntable

IPS indexing turntable machines are engineered for efficiency, precision, and versatility in high-volume shot peening applications. Designed to handle multiple parts simultaneously, these systems use automated turntables that index components through each stage of the process, ensuring consistent coverage and repeatable results. With robust construction, user-friendly controls, and the ability to integrate advanced automation or robotic features, IPS turntable machines maximize throughput while maintaining strict adherence to industry standards. Ideal for aerospace, automotive, and industrial applications, our indexing systems deliver the reliability and productivity manufacturers need to stay competitive.

CNC Rotary Table

IPS CNC rotary table machines are designed for precision peening of larger or more complex components that require controlled, programmable motion. Equipped with advanced CNC controls, these machines allow multi-axis part rotation and tilt, ensuring uniform coverage even on challenging geometries. The flexibility of rotary positioning makes them ideal for aerospace, energy, and industrial applications where accuracy and repeatability are critical. Built for durability and ease of integration, IPS rotary table machines deliver consistent results while offering the adaptability to meet evolving production requirements.

Custom Shot Peening Machines

IPS designs and engineers custom shot peening machines tailored to the most demanding applications. Our systems are built to meet strict AMS2432 compliance, ensuring precise process control and repeatability. With options such as dual media capability for flexible blasting requirements, advanced safety configurations to protect operators and equipment, and fully integrated automation features, IPS delivers solutions that go beyond standard equipment. Each machine is engineered to address unique part geometries, production volumes, and performance specifications—giving manufacturers a reliable, future-ready system built around their exact needs.

CNC Retrofits and Refurbishments

At IPS, our team of experts can rebuild or retrofit any CNC machine, saving you money compared to the cost of a new machine, and extending the life of your still functional equipment.