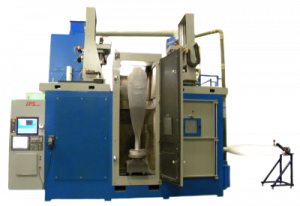

Custom Shot Peening Machines

Custom built shot peening and abrasive blasting machines with proven components to process any shape and sized part.

Consistent Accuracy

CNC motion control systems allow for consistent, precise peening.

Custom Part Enclosures

Custom part enclosures allows for special part size and part handling.

Easy Programming

CIMCAP also allows for easy programming by using mouse click commands that write CNC G code.

Built to Meet Your Unique Needs

Consistent Accuracy and Part Recipe Programming

CIMCAP Monitoring

CIMCAP monitoring system is designed for both the operator and the process engineer. Each CIMCAP system is fully configured for its specific application. Extension context sensitive help and intuitive Windows based controls make using the CIMCAP system operator friendly. CIMCAP also allows for easy programming by using mouse click commands that write CNC G code.

For example, the programmer can change the air pressure by clicking on the CIMCAP air pressure button then entering the new pressure. CIMCAP will write and enter the proper code into the part program. These quick programming buttons include, but are not limited to, dwell, axis speed, part rotation speed, air pressure, shot flow and other key parameters.

Robotic Arm Shot Peening

Articulating arm robotics can be added to the interior or exterior of all IPS machines. Normally this type of robotic motion is specific to an application, such as plastic media blasting, or a specific motion that a CNC-gantry robot cannot provide. Articulating arm robots are historically cheaper than CNC-gantry robots, but can be more expensive to repair should wear occur inside the enclosure. Articulating arm robots also require larger enclosure sizes to accommodate the robot motion. The main benefit of an articulating arm robot motion is speed and reach. Systems can also be integrated with other loading robots and multi systems tasking.

Robotic articulating arm machines offer users a fast nozzle motion for larger parts that need quick cycle timers. Customers may choose the robot of choice. Another benefit to some customers is the familiarity of robot programming. Machine enclosures are custom built to allow the robotic arm to fully move to peen or blast the users part.

Additional Features

Rotary Table

Direct pressure or gravity feed suction delivery

AMS 2430 and AMS 2432 compliant

Single or batch processing

Easy-to-use Cimcap software

Cabinet size and weight requirements can fit any part

Robotic loading integration

Integrated loading crane