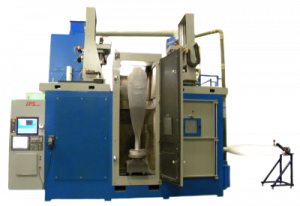

Automated Shot Peening Machines

Whether you need an abrasive blasting machine capable of peening large engine turbines or one small enough to peen small auto parts, IPS has a machine built for your exact needs.

CNC Indexing Turntable

Ideally suited for repetitive, high volume applications, our CNC indexing turntable abrasive blasting machine uses a nozzle motion control system for quick and accurate processing. Parts rotate in front of a series of nozzles that can be mounted on a combination of axis motions.

CNC Rotary Table

Available in four sizes in our standard product line along with a host of customizable options such as quantity and types of axes needed, the CNC Rotary Table Shot peening machine is a multi-use machine for precision parts that reduces the setup time of nozzles, and offers precise nozzle-to-part motion control.

Custom Shot Peening Machines

We offer custom machinery to accommodate any shape and size part when our standard machines do not fit the customer application. Custom part enclosures, axis combination and controller types, and multiple motion axis configurations are just a few of the custom options available for consistent accuracy and part programming.CNC Retrofits and Refurbishments

At IPS, our team of experts can rebuild or retrofit any CNC machine, saving you money compared to the cost of a new machine, and extending the life of your still functional equipment.

Request a quote or speak to an expert.

Frequently Asked Questions

1

Why should I shot peen parts?

Shot peening enhances parts by replacing tensile stress. Tensile stress can cause parts to fail, with compressive residual stress, which are strong and part of a design and reside in a part. Well know examples of residual stress designs are the Colosseum in Rome and the Hoover Dam.

2

Will extra peening make a part even stronger?

No, you can actually damage the fatigue life of a part by overpeening and the best way to control the peening to specification is through CNC control.

3

How can a single robotic nozzle be better than a batch or multi- nozzle machine?

A single nozzle robotic machine is better and faster than batch and multiple nozzle machines since they will cover the entire designated area to precisely 100% coverage. Batch and multi-nozzle machines can strike the same place to 300% or 400% coverage in order to get all areas to 100%, ultimately weakening the part AND increasing production time.